http://www.dnaindia.com/analysis/column-policy-watch-oh-shit-a-rs-150617-crore-business-2033671

Waste-management

Oh shit! A Rs 150,617 crore business

Biogas is finally beginning to attract some of the biggest names in the markets. Tata Power just announced that it has helped set up 36 biogas plants in and around Mundra in Gujarat. Scania, the Swedish truck and bus maker, has worked out a deal with farmers around Kolar in Karnataka, for putting all their rotting vegetables and fruit in a digestor which can produce upto 250 cubic metres of biogas a day.

There are other players too. Vinay Kore, of Warana, near Kolhapur, has set up one of the largest digestors in the country, producing 22,000 cubic metres of biogas a day from agricultural waste. He bottles this and sells them to the trucking and the hotel industry for Rs45 per litre (approximately one cubic metre), thus earning Rs9.9 lakh each day. Many more players are moving in (http://www.dnaindia.com/money/report-india-needs-a-national-policy-on-waste-management-2011519).

But biogas can be made from shit as well. Dung from humans, animals and poultry is good for biogas generation. For India this is of immense significance — because it has the second largest human population, and the largest number of cattle (Read more). If managed well, it could actually transform India into a veritable powerhouse.

Big shit indeed!

Consider this. India produces around 1.875 million tonnes of human excreta daily (this does not get classified as municipal solid waste, as it gets dismissed as sewage). It also produces around 2.06 million tonnes of animal and poultry dung. All this amounts to 1,434 million tonnes of dung each year.

Many farmers are already aware of the advantages of producing biogas from cattle dung. Some have set up small gobar gas plants across the country to aid cooking. Large poultry farmers in the Punjab also know this, and have begun using poultry droppings to produce biogas. But the processes are primitive, and the biogas quantities generated are meagre. Hence they operate at sub-optimal levels.

Yet, methane is money. As any school student of science will tell you, methane is the same combustible material that goes into cooking as LPG (Liquefied Petroleum Gas) or in vehicles as CNG (compressed natural gas). Biogas is nothing but methane, though it may have to be upgraded a bit (to become bioCNG) before it can be used as fuel for vehicles.

Even Microsoft’s Bill Gates has begun looking at this opportunity. His foundation now finances “eToilets” which collect shit from toilets into a ‘digestors’ which in turn generate methane through “floating dome gas collectors”. In other words, Microsoft is showing India a way to use a strategic resource called shit — a vision that has escaped India’s policymakers for almost seven decades.

Gobar Banks

However, Narendra Modi, currently Prime Minister of India, realised this, and started the Gobar (cattle dung) Bank scheme in Gujarat while he was its Chief Minister as a public-private-partnership initiative. But with his moving over to the Centre, the project has found no major champion within the state government as yet.

The concept is brilliant. Aware that 80% of cattle are owned by small homesteaders (2-10 cattle), only small amounts of dung get collected. Gobar Banks were intended to become the country’s first depositories for such dung —in exchange for a credit note which could be redeemed against (a) cash, (b) organic manure, (c) both, but after a period of 15 days.

This way, collection costs for dung got minimised, larger quantities of dung could be collected for large digestors, and the residual slurry could be dried and pelletised and then sold as organic manure. The dung thus generates two streams of cash — methane and organic manure.

“Each tonne of dung — animal or human — can easily generate 40-50 cubic metres of biogas,” says Srinivas Kasulla of Green Elephant Technologies. “With food waste it could be 80-100 cubic metres, while for vegetable waste it could be 60-70 cubic metres per tonne. Every 800 cubic metres of biogas, when cleaned, can yield 480 cubic metres (or 350 kg) of methane. Manure from food waste will be around 500 kg per tonne per day, though this will be higher with vegetable waste,” he adds.

Five advantages

This has several advantages.

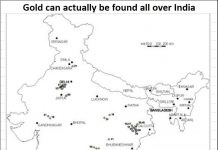

First, since people are spread out across the country, dung (or food and vegetable waste) digestors for methane extraction can be set up almost anywhere in India.

Second, this would solve the problem of open defecation on the one hand, pay for the toilet upkeep, and even leave substantial profits aside.

Third, since these digestors can be decentralised, each area could have its own methane generation plant for facilitating cooking gas. It would save the country the immediate need for gas pipes reaching out from the main national gas pipes to each remote village. What the government now has to do is to put into place a mechanism whereby such digestors are maintained, and someone is in charge for metering the creation and consumption of biogas.

Fourth, since methane would replace diesel and LPG consumption, this would save India huge foreign exchange outflows.

Fifth, it could help reduce India’s fertiliser import bill. Farms could use the organic manure these digestors produce.

There are two deterrents that turn away people from using dung as manure: (a) the smell and (b) the wet, unpleasant nature of the slurry. But both problems can be solved. If a desulfonation plan is added to the digestor, the removal of sulphur removes the bad odour (sale of the extracted sulphur pays for the process). Then, once other noxious elements (mercury, other chemicals) are removed, the residual slurry can be dried, pelletised and sold as organic manure. Dung alone can generate over 700 million tonnes of organic manure each year.

QED: Shit makes more sense than you think.

COMMENTS